Maximising ESD Protection in Industrial Workstations

ESD (Electrostatic Discharge) is a critical issue in the electronics and industrial manufacturing industries. Discharges can damage sensitive electronic components, reduce product quality, and even create safety risks.

Measuring ESD is a crucial part of ensuring that industrial workstations are protected from costly incidents and defects.

This white paper gives an overview of how to measure ESD according to the relevant ESD standards.

8 key points you’ll learn in this guide:

1. What are the current ESD standards

2. Things you should know before measuring

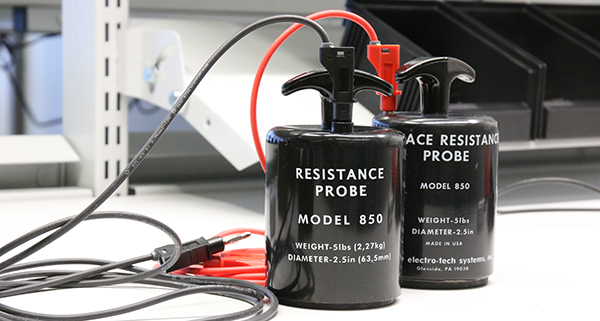

3. What are the ESD measuring equipment

4. What is a common point ground (CPG)

5. How to measure the workbenches

6. How to measure the shelves and other platforms

7. How to measure the trolleys

8. How to measure the chairs

A Complete Guide on how to measure Electrostatic discharge (ESD)

This comprehensive guide covers everything from the ESD measuring equipment to methods for measuring in your workspace.

We’ll walk you through the ESD standards and provide practical guides of how the measuring works in industrial workstations.

Easy-to-read ESD measuring guide with explanatory images and videos

Our ESD specialist, has compiled the latest information and best practices into an easy-to-read guide that will help you create a more reliable workspace to ensure the quality of your components.

Why is Measuring ESD Important?

A single ESD event can damage sensitive electronic components and lead to expensive downtime and repairs.

By measuring ESD in your workspace, you can identify potential problem areas and take proactive steps to prevent ESD incidents from occurring.

Measuring ESD White paper English_Optimized

For ESD Products and equipment, visit https://merlin-industrial.com/esd-products

If you’ve ever felt an electric jolt when getting out of your car or taking clothes out of the tumble dryer then you’ve felt ESD. Charges of static electricity build up from all the materials rubbing together and then pass through your body when they’re able to escape. Large jolts of ESD can create a visible spark, with the most impressive being that of lightning.2

If you’ve ever felt an electric jolt when getting out of your car or taking clothes out of the tumble dryer then you’ve felt ESD. Charges of static electricity build up from all the materials rubbing together and then pass through your body when they’re able to escape. Large jolts of ESD can create a visible spark, with the most impressive being that of lightning.2 In order to protect your manufacturing area against ESD you need to turn it into an anti static EPA (ESD Protected Area).4 The principle of an EPA is that all your workbenches, trolleys, storage bins and other industrial furniture is connected to the ground so that static electricity can be dissipated (dispersed) safely. Your personnel can also be equipped with conductive shoes and wrist straps to dissipate built up static electricity safely.

In order to protect your manufacturing area against ESD you need to turn it into an anti static EPA (ESD Protected Area).4 The principle of an EPA is that all your workbenches, trolleys, storage bins and other industrial furniture is connected to the ground so that static electricity can be dissipated (dispersed) safely. Your personnel can also be equipped with conductive shoes and wrist straps to dissipate built up static electricity safely.